The latest report titled “Hydrogen Cyanide Production Cost Report” by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Hydrogen Cyanide.

Procurement Resource study is based on the latest prices and other economic data available. It also offers additional analysis of the report with detailed breakdown of all cost components (capital investment details, production cost details, economics for another plant location, dynamic cost model). In addition, the report incorporates the manufacturing process with detailed process and material flow, capital investment, operating costs along with financial expenses and depreciation charges.

Procurement Resource’s detailed report describes the stepwise consumption of material and utilities along with a detailed process flow diagram. Furthermore, the study assesses the latest developments within the industry that might influence Hydrogen Cyanide production cost, looking into capacity expansions, plant turnarounds, mergers, acquisitions, and investments.

Request for Sample: https://www.procurementresource.com/production-cost-report-store/hydrogen-cyanide/request-sample

Procurement Resource Assessment of Hydrogen Cyanide Production Process:

1. Hydrogen Cyanide Production From Andrussow Oxidation: The study offers a detailed cost analysis of Hydrogen Cyanide production via Andrussow Oxidation. In the Andrussow oxidation, methane and ammonia are reacted in the presence of oxygen over a platinum catalyst at about 1200 °C. This is the most popular method of production.

Request Free Sample – https://www.procurementresource.com/cost-analysis/hydrogen-cyanide-production-by-andrussow-oxidation/requestsample

2. Hydrogen Cyanide Production From Degussa Process: This report provides a detailed cost analysis of Hydrogen Cyanide production through Degussa Process. The hydrogen cyanide production is done using the Degussa process (or BMA process) in which no oxygen is added (unlike the Andrussow oxidation), and the energy is transferred indirectly through the reactor wall while methane and ammonia are reacted.

Request Free Sample – https://www.procurementresource.com/cost-analysis/hydrogen-cyanide-production-by-degussa-process/requestsample

3. Hydrogen Cyanide Production From Hydrocarbons: This report covers a detailed cost analysis of Hydrogen Cyanide production using Hydrocarbons. Using Shawinigan Process in which hydrocarbons, e.g., propane, are reacted with ammonia, Hydrogen Cyanide is produced.

Request Free Sample – https://www.procurementresource.com/cost-analysis/hydrogen-cyanide-production-from-hydrocarbons/requestsample

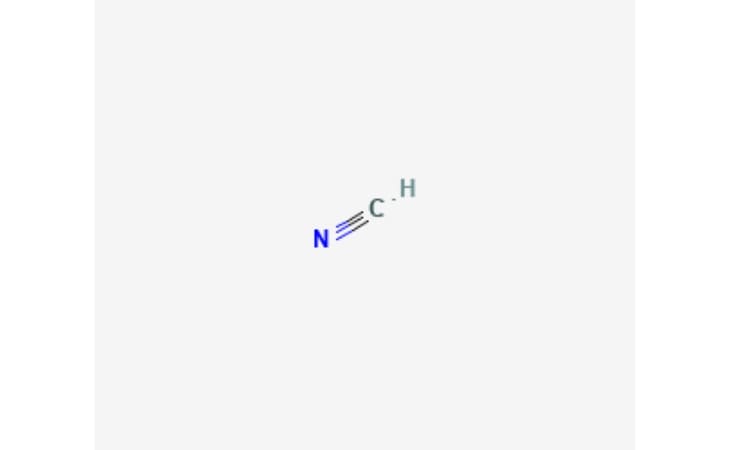

Product Definition:

Hydrogen cyanide is a colourless chemical compound, which is also called prussic acid. Hydrogen cyanide boils slightly above room temperature at 25.6 °C or 78.1 °F and is a highly flammable and poisonous chemical. From polymers to pharmaceuticals, hydrogen peroxide is a valuable precursor to various chemical compounds and is prepared commercially. The structural formula of hydrogen peroxide is HCN, and its molecular weight is 27.02 g/mol. Hydrogen cyanide is produced through Ammonia and Methane.

Market Drivers:

The hydrogen Cyanide market is witnessing growth due to the rising demand for sodium cyanide and potassium cyanide manufacturing and the growing applications of HCN in Adiponitrile production. In addition, the increasing application of adiponitrile is also driving up the demand for the product as it is a key raw material in making adiponitrile which is turned into nylon 66 for fibre and plastic production.

Key Questions Answered in the Hydrogen Cyanide Production Cost Report:

A comprehensive hydrogen cyanide production cost report typically addresses various key questions related to the production process, economic viability, and market dynamics. Here are some key questions that such a report might cover:

- Production Process Overview: What are the primary methods for producing hydrogen cyanide? What are the chemical reactions involved in each method? What are the main feedstocks required for production?

- Feedstock Sourcing and Pricing: Where do producers typically source their feedstocks for hydrogen cyanide production? What are the typical prices for these feedstocks? How do fluctuations in feedstock prices impact the overall production cost?

- Capital Investment: What are the capital investment requirements for setting up a hydrogen cyanide production facility? What are the major components of capital expenditure, such as equipment, infrastructure, and technology?

- Operating Costs: What are the major components of operating costs in hydrogen cyanide production? How do factors such as energy consumption, labor costs, maintenance, and regulatory compliance impact operating expenses?

- Economies of Scale: How do economies of scale influence the production cost of hydrogen cyanide? What are the typical production capacities of hydrogen cyanide plants, and how does scale affect cost per unit of production?

- Technology and Process Efficiency: What are the latest technological advancements in hydrogen cyanide production? How do improvements in process efficiency and catalysts impact production costs?

- By-Product Management: What are the by-products generated during hydrogen cyanide production, and how are they managed? Are there opportunities to monetize or utilize these by-products to offset production costs?

- Market Dynamics: What are the current market trends and dynamics affecting the supply and demand for hydrogen cyanide? How do factors such as industry growth, regulatory policies, and competitor actions influence pricing and profitability?

- Regional Variances: Are there significant regional variances in hydrogen cyanide production costs? What factors contribute to cost discrepancies across different geographic regions?

- Profitability Analysis: What are the typical profit margins associated with hydrogen cyanide production? How do production costs compare to market prices, and what factors impact the overall profitability of hydrogen cyanide production facilities?

These questions help stakeholders, including producers, investors, and policymakers, gain a comprehensive understanding of the cost structure, market dynamics, and profitability considerations associated with hydrogen cyanide production.

About Us:

Procurement Resource ensures that our clients remain at the vanguard of their industries by providing actionable procurement intelligence with the help of our expert analysts, researchers, and domain experts. Our team of highly seasoned analysts undertakes extensive research to provide our customers with the latest and up-to-date market reports, cost models, price analysis, benchmarking, and category insights, which aid in simplifying the procurement process for our clientele.

Procurement Resource work with a diverse range of procurement teams across industries to get real-time data and insights that can be effectively implemented by our customers. As a team of experts, we also track the prices and production costs of an extensive range of goods and commodities, thus, providing you with updated and reliable data.

We, at Procurement Resource, with the help of the latest and cutting-edge techniques in the industry, help our clients understand the supply chain, procurement, and industry climate so that they can form strategies that ensure their optimum growth.

Contact Us:

Company Name: Procurement Resource

Contact Person: Chris Byrd

Email: sales@procurementresource.com

Toll Free Number: USA & Canada – Phone no: +1 307 363 1045 | UK – Phone no: +44 7537 132103 | Asia-Pacific (APAC) – Phone no: +91 1203185500

Address: 30 North Gould Street, Sheridan, WY 82801, USA