Introduction

The abrasives market is a dynamic landscape encompassing various categories, each designed to address specific industrial requirements. Coated abrasives, exemplified by industry stalwarts like 3M’s sandpaper, stand out for their versatility in surface sanding applications. These abrasives play a pivotal role in preparing and refining surfaces across industries, offering efficiency and precision. On the other hand, bonded abrasives, represented by renowned products like Norton’s grinding wheels, bring a level of precision to cutting and grinding applications. These abrasives are engineered to deliver accuracy and reliability, making them indispensable in tasks that demand meticulous results. Additionally, super abrasives, such as the diamond tools manufactured by industry leader Saint-Gobain, represent the pinnacle of high-performance solutions. These abrasives excel in addressing the most demanding tasks, showcasing exceptional durability and efficiency. Collectively, the diverse categories within the abrasives market, each exemplified by these notable products, contribute significantly to meeting the multifaceted needs of industries, enhancing overall efficacy and functionality.

Definition

Hard materials called abrasives are used to shape, cut, polish, and grind other materials by causing friction to wear away particles. Abrasives, which are made of different minerals like silicon carbide or aluminium oxide, are essential in manufacturing processes because they allow for accurate finishes, material removal, and surface smoothing in sectors like metalworking, woodworking, and automobile production.

Fundamentals of Abrasives Market

- Technological Developments Increase Manufacturing Process Efficiency

Improvements in performance, efficiency, and application adaptability are driven by ongoing developments in abrasive materials across several sectors. Improved cutting, grinding, and polishing capabilities are the outcome of abrasive innovation, which makes industrial processes more accurate and efficient. These continuous advancements lead to higher output and the capacity to handle different material problems in different applications.

-

Improving Construction and Manufacturing Procedures Worldwide

Globalization-driven growth in emerging nations’ manufacturing and construction industries drives up demand for abrasives. The requirement for effective material processing increases as these markets grow, which propels the use of cutting-edge abrasive technology. Abrasives are essential for maximising building and manufacturing operations because they guarantee accuracy and longevity. This rise in demand emphasises how crucial abrasives are to the expansion and advancement of companies in the framework of international economic integration.

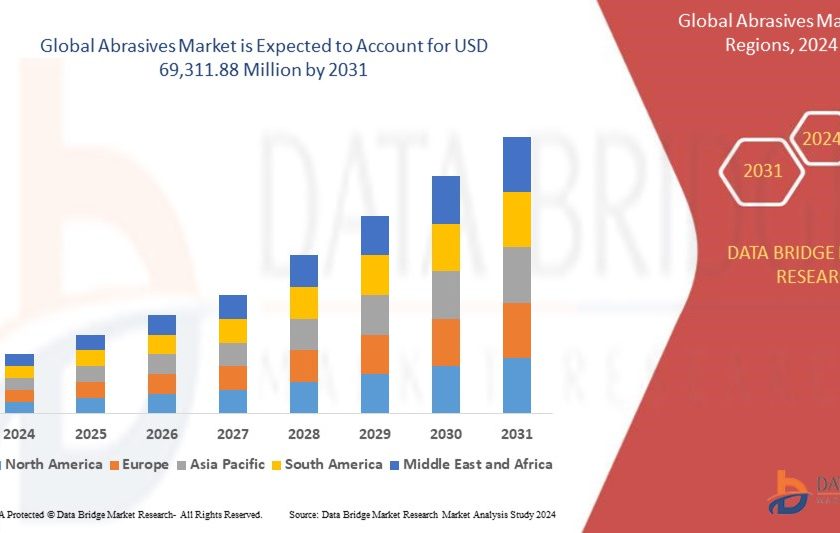

Growth rate in Abrasives Market

- According to the comprehensive analysis conducted by Data Bridge Market Research, the global abrasives market is on a trajectory to reach a substantial valuation of USD 69,311.88 million by the year 2031, experiencing a noteworthy growth from USD 45,854.37 million in 2023.

- This anticipated growth reflects a commendable Compound Annual Growth Rate (CAGR) of 5.3% during the forecast period spanning from 2024 to 2031. Within the market segments, the “Synthetic” category takes precedence, asserting dominance due to its manufacturing ease and properties that are equivalent to natural abrasives. The widespread adoption of synthetic abrasives underscores their versatility and efficiency across various industrial applications. Beyond providing insights into fundamental market parameters such as value, growth rate, and segmentation, the reports curated by Data Bridge Market Research offer an in-depth expert analysis.

- Additionally, they delve into geographically represented company-wise production and capacity, illustrating the market’s global landscape. The reports also encompass network layouts of distributors and partners, detailed and updated price trend analysis, and a deficit analysis of the supply chain and demand. This comprehensive approach ensures that stakeholders are equipped with a thorough understanding of the global abrasives market dynamics, facilitating informed decision-making in the evolving industrial landscape.

Critical role of abrasives in manufacturing processes

- The critical role of abrasives in manufacturing processes cannot be overstated, as these materials play a fundamental role in shaping, finishing, and refining various products across industries. Abrasives are integral to manufacturing operations, contributing to precision and quality in the production of a wide range of materials.

- One of the primary functions of abrasives is material removal. In shaping processes like grinding, cutting, and polishing, abrasives effectively remove excess material, ensuring that the final product adheres to precise specifications. This is particularly crucial in industries such as metalworking, where intricate components require exact dimensions.

- Abrasives also play a key role in surface finishing. Whether it’s smoothing rough surfaces, removing imperfections, or achieving a specific texture, abrasives are indispensable in creating the desired aesthetic and functional properties of a product. This is evident in industries like automotive manufacturing, where smooth and polished surfaces are essential for both performance and visual appeal.

- Moreover, the use of abrasives extends to the preparation of surfaces for coatings and treatments. Prior to painting, coating, or bonding, materials often need to be prepared to ensure optimal adhesion and durability. Abrasives facilitate this preparation by creating a clean and properly textured surface, enhancing the effectiveness of subsequent treatments.

- In manufacturing processes, efficiency and precision are paramount, and abrasives contribute significantly to both. For example, in the semiconductor industry, where precision is critical, abrasives are used in the manufacturing of electronic components to achieve the required levels of accuracy and smoothness.

- Furthermore, the versatility of abrasives is evident in their applications across diverse materials, including metals, ceramics, composites, and more. This adaptability makes abrasives suitable for a wide array of manufacturing processes, from heavy-duty industrial operations to delicate tasks requiring fine detailing.

For more information about market visit

https://www.databridgemarketresearch.com/reports/global-abrasive-market

Why choose us

Data Bridge Market Research is known for its team of experienced analysts and researchers who possess deep industry knowledge. Their expertise enables them to provide thorough and insightful analyses of various markets, industries, and sectors.

The market reports curated by Data Bridge Market Research are comprehensive and cover various aspects, including market value, growth rate, segmentation, geographical coverage, major players, and in-depth expert analysis. These reports provide a holistic view of the market landscape.

Data Bridge Market Research covers a wide range of industries, including healthcare, technology, chemicals, materials, and more. This extensive industry coverage allows businesses to access insights tailored to their specific sector.