In the dynamic landscape of the chemical industry, staying informed about the latest trends and price movements is crucial. This blog post aims to provide you with comprehensive insights into the ethylene oxide market, covering its prices, trends, and forecasts across different regions globally—Asia, Europe, North America, Latin America, and the Middle East & Africa.

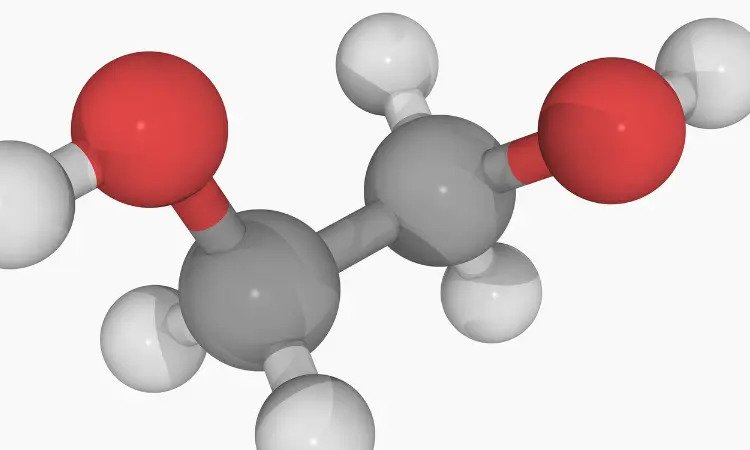

Definition of Ethylene Oxide

Ethylene oxide (EO) is a vital chemical compound used primarily in the production of various everyday products like antifreeze, textiles, detergents, and solvents. Several factors, including supply and demand dynamics, raw material costs, global economic conditions, and regulatory changes influence the price trends of ethylene oxide.

The pricing of ethylene oxide can be volatile due to its dependence on the availability and cost of its primary raw material, ethylene. Ethylene, in turn, is linked to the price trends of crude oil and natural gas as it’s predominantly derived from these sources.

Supply-demand imbalances can significantly impact EO prices. Increased demand from sectors like healthcare (where EO is used for sterilization) or the automotive industry (in antifreeze production) can drive prices up. Conversely, oversupply due to expanded production capacities or decreased demand can cause prices to drop.

Government regulations and environmental policies also influence EO prices. Changes in regulations regarding safety standards or environmental considerations can lead to production alterations or increased compliance costs, affecting the final price of ethylene oxide.

Tracking historical price trends is essential for businesses reliant on EO, aiding in strategic planning and budgeting. Generally, factors impacting EO prices are multifaceted, making its price trends complex and subject to various external influences.

Request for Real-Time Ethylene Oxide (EO) Prices: https://www.procurementresource.com/resource-center/ethylene-oxide-price-trends/pricerequest

Understanding the procurement of ethylene oxide is essential for businesses and industries relying on this crucial chemical. Procuring ethylene oxide involves a series of processes, from raw material acquisition to production methods. This section will explore the procurement resource chain, shedding light on the intricacies involved in obtaining ethylene oxide for industrial use.

Key Details About Ethylene Oxide Price Trends

Ethylene oxide (EO) prices are influenced by various factors, including supply-demand dynamics, raw material costs, and global market conditions. Historically, EO prices have shown volatility due to its significance in manufacturing various products like plastics, antifreeze, solvents, and detergents.

In recent years, EO prices experienced fluctuations due to shifts in supply caused by plant shutdowns, maintenance, or unexpected outages. Additionally, fluctuations in crude oil prices impact EO prices, as ethylene, a primary feedstock for EO production, is derived from crude oil.

The COVID-19 pandemic significantly impacted EO prices due to disrupted supply chains and fluctuating demand. Initially, prices dropped as global economic activities slowed down, but they later recovered as industries adapted to the new normal.

Geopolitical tensions, trade policies, and environmental regulations can also affect EO prices. For instance, stringent environmental norms might lead to increased production costs, influencing market prices.

Industrial Uses Impacting Ethylene Oxide Price Trends

Ethylene oxide (EO) is a pivotal compound in various industrial applications, and its price trends are intricately tied to market demands and supply dynamics. Several key industries significantly impact EO prices:

- Polymer Manufacturing: EO is crucial in producing ethylene glycol, a primary component in polyester fibers and antifreeze. Fluctuations in polyester demand, influenced by consumer behavior and economic shifts, directly affect EO prices.

- Surfactants and Detergents: EO is a core ingredient in surfactants and detergents, forming the backbone of many cleaning products. Consumer preferences for eco-friendly cleaners and changes in cleaning habits influence EO demand and thus its pricing.

- Medical Equipment Sterilization: EO’s effectiveness in sterilizing medical equipment drives demand in the healthcare sector. Healthcare advancements, pandemics, or regulatory changes impacting medical practices can affect EO prices.

- Agrochemicals: EO contributes to the synthesis of herbicides, pesticides, and fungicides. Changes in agriculture practices, weather patterns affecting crop diseases, and regulatory alterations can impact EO prices in this sector.

- Automotive Industry: Ethylene glycol produced from EO is used in automotive antifreeze. Fluctuations in the automotive sector, such as changes in vehicle production or shifts towards electric vehicles, can influence EO demand and prices.

- Other Applications: EO is also utilized in pharmaceuticals, personal care products, and plasticizers, with demand influenced by innovation, consumer trends, and regulatory changes.

Moreover, factors like raw material costs (such as ethylene), technological advancements impacting production efficiency, geopolitical events affecting supply chains, and environmental regulations governing EO production also contribute significantly to price trends in the industry.

Key Players in the Ethylene Oxide Market

The ethylene oxide market involves several key players contributing to its growth and development. Companies like Dow Chemical Company, Shell Chemicals, BASF SE, SABIC, and Huntsman Corporation are prominent entities in this sector. Dow Chemical Company, a global leader in chemical manufacturing, has a significant presence in ethylene oxide production, utilizing it in various applications such as detergents, solvents, and chemical intermediates. Shell Chemicals, a subsidiary of Royal Dutch Shell, is also a major player, leveraging ethylene oxide in producing ethylene glycol, surfactants, and other chemicals.

BASF SE, a multinational chemical company, is involved in ethylene oxide production for manufacturing products like polyurethanes, glycol ethers, and surfactants. SABIC, a Saudi Arabian petrochemicals company, focuses on ethylene oxide for producing glycol ethers, ethoxylates, and other downstream chemicals. Huntsman Corporation specializes in ethylene oxide derivatives like ethylene glycol, a crucial component in the production of PET resin used in packaging.

These companies play a pivotal role in shaping the ethylene oxide market, driving innovation, and meeting diverse industry demands while ensuring quality and sustainability in their operations.

Regional Analysis of Ethylene Oxide Prices, Trends, and Forecasts

To provide a comprehensive view, this section will break down the ethylene oxide market by region. Analyzing trends in Asia, Europe, North America, Latin America, and the Middle East & Africa will offer valuable insights into the regional dynamics shaping ethylene oxide prices. Factors such as regulatory environments, market demand, and geopolitical influences will be explored to paint a complete picture of the global ethylene oxide landscape.

Forecasting the Future: Ethylene Oxide Market Outlook

In the final section of this blog post, we will gaze into the crystal ball and provide forecasts for the ethylene oxide market. What does the future hold in terms of pricing trends? How will geopolitical shifts impact the industry? These are the questions we aim to answer, offering readers valuable insights for strategic decision-making in a rapidly evolving market.

Conclusion

As we conclude this exploration of ethylene oxide prices, trends, and forecasts, it’s evident that staying informed is key to navigating the complex dynamics of the chemical industry. Whether you’re a manufacturer, distributor, or stakeholder in the ethylene oxide market, the insights provided in this blog post are designed to equip you with the knowledge needed to make informed decisions and stay ahead of the curve in this ever-evolving landscape.