IMARC Group, a leading market research company, has recently releases report titled “Die Casting Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2032” offers a comprehensive analysis of the industry, which comprises insights on the die casting market forecast. The global market size reached US$ 66.1 Billion in 2023. Looking forward, IMARC Group expects the market to reach US$ 108.0 Billion by 2032, exhibiting a growth rate (CAGR) of 5.44% during 2024-2032.

Request For Sample Copy of Report: https://www.imarcgroup.com/die-casting-market/requestsample

Factors Affecting the Growth of the Die Casting Industry:

- Focus on Sustainable and Eco-Friendly Practices:

There is a rise in the adoption of eco-friendly manufacturing practices and the use of recyclable materials, especially in industries like automotive and consumer electronics, which are under pressure to reduce their environmental footprint. This encourages the employment of die casting due to its compatibility with recyclable metals like aluminum and magnesium. Additionally, advancements in die casting technology are leading to more energy-efficient processes with reduced waste and emissions. This shift towards sustainability is also driven by regulatory compliance and the need for greener products.

- Demand for High-Pressure Die Casting (HPDC):

There is an increase in the demand for HPDC to produce dense, dimensionally accurate components with smooth surfaces, which are essential in high-specification industries like automotive, aerospace, and electronics. The ability of HPDC to produce large volumes of complex shapes at high speed and with consistent quality makes it particularly attractive. The shift towards lightweighting high-strength alloys is prompting the adoption of HPDC as it provides manufacturers with efficient, cost-effective, and high-quality casting method to meet the growing complexity of product designs.

- Technological Advancements:

Technological advancements in die casting processes are enhancing efficiency, product quality, and environmental sustainability. The rising innovations, such as vacuum die casting, squeeze die casting, and semi-solid die casting, are also expanding the capabilities and applications of die casting. The advent of modern computer-aided engineering (CAE) technologies and simulations is enhancing the precision in die design and reducing the time and cost involved in prototyping and production. Additionally, automation and robotics in die casting processes are increasing production rates and consistency while reducing labor costs and human error. These technological improvements also enhance the quality and range of die-cast products.

Leading Companies Operating in the Global Die Casting Industry:

- Dynacast International Inc. (Form Technologies Inc.)

- Endurance Technologies Limited

- Georg Fischer Ltd.

- Gibbs Die Casting Corp. (Koch Enterprises Inc.)

- Nemak S.A.B. de C.V.

- Pace Industries (Leggett & Platt)

- Rheinmetall AG

- Rockman Industries

- Ryobi Die Casting (USA) Inc. (Ryobi Limited)

- Sandhar Technologies Limited

- Shiloh Industries Inc. and Sundaram – Clayton Limited.

Die Casting Market Report Segmentation:

By Process:

- Pressure Die Casting

- Vacuum Die Casting

- Squeeze Die Casting

- Others

Pressure die casting holds the largest market share due to its efficiency and cost-effectiveness.

By Raw Material:

- Aluminum

- Magnesium

- Zinc

Aluminum represents the biggest segment on account of its lightweight properties and suitability for various applications.

By Application:

- Automobile

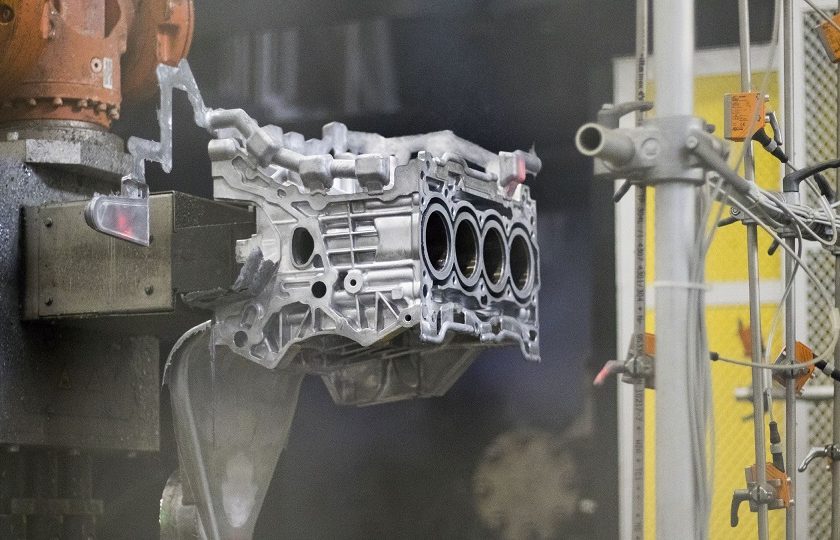

- Body Parts

- Engine Parts

- Transmission Parts

- Others

- Heavy Equipment

- Construction

- Farming

- Mining

- Machine Tools

- Plant Machinery

- Chemical Plants

- Petroleum Plants

- Thermal Plants

- Paper

- Textile

- Others

- Municipal Castings

- Valves and Fittings

- Pipes

- Others

Automobile accounts for the majority of the market share, driven by the escalating demand for die-cast components in automotive manufacturing.

Regional Insights:

- North America (United States, Canada)

- Asia Pacific (China, Japan, India, South Korea, Australia, Indonesia, Others)

- Europe (Germany, France, United Kingdom, Italy, Spain, Russia, Others)

- Latin America (Brazil, Mexico, Others)

- Middle East and Africa

Asia-Pacific dominates the die casting market, mainly due to the robust industrial growth and manufacturing activities in the region.

Global Die Casting Market Trends:

The shift towards lightweight materials, particularly in the automotive and aerospace industries, is driving the demand for die casting for creating parts offering fuel efficiency and emission reduction. This is also leading to an increased use of aluminum and magnesium alloys in die casting, which offer the necessary strength-to-weight ratio crucial for modern vehicle and aircraft designs.

In addition, the expansion of die casting applications in renewable energy and medical devices represents another key trend. The components for solar panels and wind turbines benefit from the strength and reliability of die cast parts, and in the medical field, the demand for precision instruments and equipment with complex geometries is making die casting a preferred manufacturing method. This diversification into new sectors not only broadens the market scope for die casting but also drives innovation in the market.

Other Key Points Covered in the Report:

- Porters Five Forces Analysis

- Value Chain Analysis

- Strategic Recommendations

About Us

IMARC Group is a leading market research company that offers management strategy and market research worldwide. We partner with clients in all sectors and regions to identify their highest-value opportunities, address their most critical challenges, and transform their businesses.

IMARC Group’s information products include major market, scientific, economic and technological developments for business leaders in pharmaceutical, industrial, and high technology organizations. Market forecasts and industry analysis for biotechnology, advanced materials, pharmaceuticals, food and beverage, travel and tourism, nanotechnology and novel processing methods are at the top of the company’s expertise.

Contact US

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145 | United Kingdom: +44-753-713-2163